DFT: Check Valves:

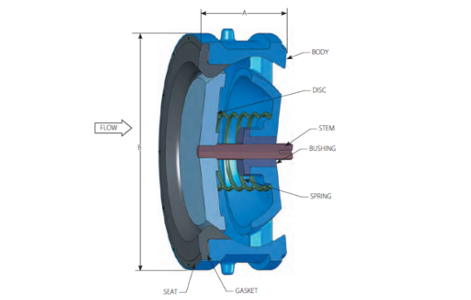

ALC® Wafer Check Valve

|

|

| Documentation: Product Specifications (169KB PDF) |  |

Check Valve Operation:

Check valves are flow sensitive and rely on the line fluid to open and close. The internal disc allows flow to pass forward, which opens the valve. The disc begins closing the valve as forward flow decreases or is reversed, depending on the design. The function or purpose of a check valve is to prevent reverse flow.

Internal sealing of the check valve disc and seat relies on “reverse” line pressure as opposed to the mechanical force used for on/off valves. Because of this, allowable seat leakage rates are greater for check valves than with on/off valves.

|

Materials of Construction |

Carbon Steel Body | Stainless Steel Body |

|---|---|---|

| Body | A216 Grade WCB | A351 CF8M |

| Disc/Stem Assembly | 316 SS/Nitronic® 60 | 316 SS/Nitronic® 60 |

| Seat | 316 SS | 316 SS |

| Spring | Inconel® X-750 | Inconel® X-750 |

| Bushing | 316 SS | 316 SS |

| Gasket | CFG | CFG |

| ALC Wafer Check Valve

|

Options:

|

|

The lightweight compact design fits between mating flanges and meets API 594 Face-to-Face dimensions. The ALC Check Valve is an easy-to-maintain check valve for applications involving liquids, gases or steam. Tapped holes are provided in the body for lifting lugs to assist with installation (10” and larger sizes.)

| ALC Wafer Check Valve | Class | 150 RF | 300 RF |

|---|---|---|---|

| 2" | Dim A | 2.38 | 2.38 |

| Dim B | 4.25 | 4.25 | |

| Weight | 5.8 | 5.8 | |

| Cv | 120 | 120 | |

| CP | 0.65 | 0.65 | |

| 2-1/2" | Dim A | 2.62 | 2.62 |

| Dim B | 5.00 | 5.00 | |

| Weight | 8.8 | 8.8 | |

| Cv | 205 | 205 | |

| CP | 0.69 | 0.69 | |

| 3" | Dim A | 2.88 | 2.88 |

| Dim B | 5.75 | 5.75 | |

| Weight | 12.8 | 12.8 | |

| Cv | 260 | 260 | |

| CP | 0.63 | 0.63 | |

| 4" | Dim A | 2.88 | 2.88 |

| Dim B | 7.00 | 7.00 | |

| Weight | 17.4 | 17.4 | |

| Cv | 430 | 430 | |

| CP | 0.59 | 0.59 | |

| 6" | Dim A | 3.88 | 3.88 |

| Dim B | 9.75 | 9.75 | |

| Weight | 38 | 38 | |

| Cv | 825 | 825 | |

| CP | 0.59 | 0.59 | |

| 8" | Dim A | 5.00 | 5.00 |

| Dim B | 12.00 | 12.00 | |

| Weight | 68.8 | 68.8 | |

| Cv | 1310 | 1310 | |

| CP | 0.55 | 0.55 | |

| 10" | Dim A | 5.75 | 5.75 |

| Dim B | 14.13 | 14.13 | |

| Weight | 115 | 115 | |

| Cv | 1875 | 1875 | |

| CP | 0.53 | 0.53 | |

| 12" | Dim A | 7.13 | 7.13 |

| Dim B | 16.50 | 16.50 | |

| Weight | 200 | 200 | |

| Cv | 2525 | 2525 | |

| CP | 0.53 | 0.53 | |

| 14" | Dim A | 7.25 | 8.75 |

| Dim B | 17.63 | 19.00 | |

| Weight | 225 | 320 | |

| Cv | 2950 | 3275 | |

| CP | 0.55 | 0.55 | |

| 16" | Dim A | 7.50 | 9.13 |

| Dim B | 20.13 | 21.31 | |

| Weight | 315 | 425 | |

| Cv | 3330 | 4100 | |

| CP | 0.50 | 0.50 | |

| 18" | Dim A | 8.00 | 10.38 |

| Dim B | 21.50 | 23.25 | |

| Weight | 390 | 618 | |

| Cv | 3475 | 5040 | |

| CP | 0.55 | 0.55 | |

| 20" | Dim A | 8.62 | 11.50 |

| Dim B | 23.75 | 25.63 | |

| Weight | 545 | 760 | |

| Cv | 3750 | 6050 | |

| CP | 0.54 | 0.57 | |

| 24" | Dim A | 8.75 | 12.50 |

| Dim B | 28.13 | 30.38 | |

| Weight | 745 | 1200 | |

| Cv | 5150 | 8325 | |

| CP | 0.52 | 0.57 | |

| Not recommended for use on discharge of reciprocating compressors. | |||