DFT: Check Valves:

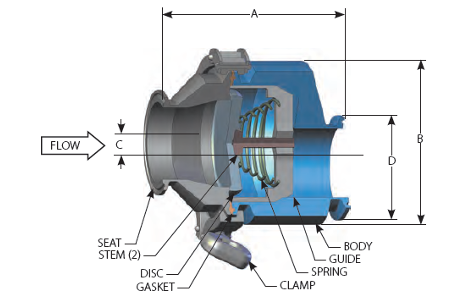

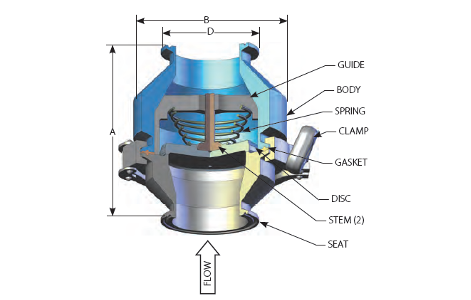

DSV® Sanitary Check Valve

|

|

| Documentation: Product Specifications (166KB PDF) |  |

The DSV Check Valve is fastened with a quick release clamp and elastomeric body seal to permit fast and easy access to the internals. The internal surface finish is 25 Ra while the disc and seat are lapped to provide excellent shutoff.

| Materials of Construction: | |

|---|---|

| Component | |

| Body | A351 CF3M |

| Seat | A351 CF3M |

| Disc | 316 SS |

| Spring | 316 SS (electropolished) |

| Guide Assembly | 316 SS |

| Body Seal | EPDM (-75°F to 300°F) |

| Clamp | 304 SS |

| Internal Surface Finish | 25 Ra |

| DSV Sanitary Horizontal |

| DSV Sanitary Vertical |

| Horizontal | Vertical | |||

|---|---|---|---|---|

| 1/2" | Dim A | 2.5 | Dim A | 2.5 |

| Dim B Dia | 1.5 | Dim B Dia | 0.98 | |

| Dim C | 0.44 | Dim D Dia | 0.98 | |

| Dim D Dia | 0.98 | Weight | 1.4 | |

| Weight | 1.4 | Cv | 2.4 | |

| Cv | 2.4 | CP (Flow Down) | 0.26 | |

| CP | 0.29 | CP (Flow Up) | 0.33 | |

| 3/4" | Dim A | 2.5 | Dim A | 2.25 |

| Dim B | 1.5 | Dim B Dia | 0.98 | |

| Dim C | 0.31 | Dim D Dia | 0.98 | |

| Dim D Dia | 0.98 | Weight | 1.4 | |

| Weight | 1.3 | Cv | 7 | |

| Cv | 7 | CP (Flow Down) | 0.26 | |

| CP | 0.29 | CP (Flow Up) | 0.33 | |

| 1" | Dim A | 3.48 | Dim A | 2.92 |

| Dim B Dia | 3 | Dim B Dia | 2 | |

| Dim C | 0.5 | Dim D Dia | 1.98 | |

| Dim D Dia | 1.98 | Weight | 2.3 | |

| Weight | 3.7 | Cv | 18 | |

| Cv | 12 | CP (Flow Down) | 0.31 | |

| CP | 0.36 | CP (Flow Up) | 0.41 | |

| 1-1/2" | Dim A | 3.67 | Dim A | 3.29 |

| Dim B Dia | 3.12 | Dim B Dia | 2.5 | |

| Dim C | 0.5 | Dim D Dia | 1.98 | |

| Dim D Dia | 1.98 | Weight | 2.8 | |

| Weight | 4 | Cv | 38 | |

| Cv | 36 | CP (Flow Down) | 0.23 | |

| CP | 0.28 | CP (Flow Up) | 0.33 | |

| 2" | Dim A | 4.41 | Dim A | 4.03 |

| Dim B Dia | 3.62 | Dim B Dia | 3 | |

| Dim C | 0.5 | Dim D Dia | 2.52 | |

| Dim D Dia | 2.52 | Weight | 5.8 | |

| Weight | 3.9 | Cv | 47 | |

| Cv | 53 | CP (Flow Down) | 0.16 | |

| CP | 0.23 | CP (Flow Up) | 0.31 | |

| 2-1/2" | Dim A | 5.56 | Dim A | 5.56 |

| Dim B Dia | 4.75 | Dim B Dia | 4 | |

| Dim C | 0.73 | Dim D Dia | 3.05 | |

| Dim D Dia | 3.05 | Weight | 11.2 | |

| Weight | 9.9 | Cv | 69 | |

| Cv | 81 | CP (Flow Down) | 0.42 | |

| CP | 0.54 | CP (Flow Up) | 0.66 | |

| 3" | Dim A | 4.88 | Dim A | 4.38 |

| Dim B Dia | 4.75 | Dim B Dia | 4 | |

| Dim C | 0.48 | Dim D Dia | 3.58 | |

| Dim D Dia | 3.58 | Weight | 6.1 | |

| Weight | 9.9 | Cv | 109 | |

| Cv | 90 | CP (Flow Down) | 0.42 | |

| CP | 0.54 | CP (Flow Up) | 0.66 | |

| 4" | Dim A | 6.25 | Dim A | 5.5 |

| Dim B Dia | 7 | Dim B Dia | 6 | |

| Dim C | 0.97 | Dim D Dia | 4.68 | |

| Dim D Dia | 4.68 | Weight | 14.9 | |

| Weight | 22.2 | Cv | 174 | |

| Cv | 137 | CP (Flow Down) | 0.4 | |

| CP | 0.5 | CP (Flow Up) | 0.6 | |

Check Valve Operation:

Check valves are flow sensitive and rely on the line fluid to open and close. The internal disc allows flow to pass forward, which opens the valve. The disc begins closing the valve as forward flow decreases or is reversed, depending on the design. The function or purpose of a check valve is to prevent reverse flow.

Internal sealing of the check valve disc and seat relies on “reverse” line pressure as opposed to the mechanical force used for on/off valves. Because of this, allowable seat leakage rates are greater for check valves than with on/off valves.

The longest trouble-free service will come from valves sized for the application, not the line size, whereby the disc is stable against the internal stop in the open position or fully closed. When these conditions are met, no fluttering of the disc will occur (resulting in premature failure.)

Check valve internals are flow sensitive. If there is not enough flow disc movement occurs inside the valve resulting in wear, potential failure, and a higher pressure drop than calculated.