Industrial Data Collection

Analysis and Control

Temperature • Humidity • Flow Rate

The DXN Ultrasonic Hybrid Portable Flow Meter

The DXN can measure the flow of pure liquids as well as liquids with entrained solids or aeration. The transmitter will switch between transit time and Doppler measurements on the fly based on the condition of the media inside the pipe.

At Derex, Inc. our entire rental fleet consists of DXN flowmeters. Our rental units experience a wide variety of applications and conditions and the DXN has proven itself to be reliable, rugged, accurate and maintenance-free.

This unit can measure: Flow Rate, Temperature in Liquid.

Rentals Include:

- DXN Transmitter:

- Transit Time / Doppler Hybrid Ultrasonic

- 1 gb onboard data logger storage

- AC/DC, li ion battery + auxiliary connections

- Transducers:

- 3 Transit Time sets (Small, Medium & Large)

- 1 Doppler set

- 1 Pipe Thickness Sensor

- Output Junction Box:

- 4-20 mA

- Digital Output (OC)

- Voltage Output, etc.

- USB Thumb Drive

- Contains the Digital Manual

- Save / Export Logs to your PC in Excel format

- All Cables and Carrying Cases

- *RTD Thermal Sensors available on request

The DXN Portable Ultrasonic Flow and Energy Meter is a true hybrid instrument, capable of measuring liquid flow with multiple technologies, including: Doppler, transit time and liquid thermal (heat energy) flow. Easy to install by clamping onto the outside of the pipe, the DXN measures flow using non-invasive ultrasonic sensors. Compatible with a pipe wall thickness gauge, inside pipe diameter can be verified to ensure accurate ultrasonic measurements when piping details are unknown or unavailable.

The DXN has a number of advanced features including a touchscreen interface, full-color graphing, wizard-based start-up configuration, USB connectivity, and Modbus TCP/IP connectivity. These features make it easy for technicians to obtain accurate readings while capturing flow surges and high-speed batch operations.

The DXN captures and displays multiple user-defined and application parameters at once and can record the data with an easy-to-use data logging function. The ability to monitor and record several parameters at once allows technicians to verify and troubleshoot permanent flow installations with ease. The compact design fits the meter and accessories into one convenient over-the-shoulder bag for easy portability. Applications include clean, solids-bearingor aerated liquids in closed full pipes 1/2 inch(12 mm) and larger.

OPERATION:

Transit time flow meters measure the time difference between the travel time of an ultrasound wave going with the fluid flow and then against the fluid flow. This time difference is used to calculate the velocity of the fluid traveling in a closed-pipe system. The transducers used in transit time measurements operate alternately as transmitters and receivers. Transit time measurements are bi-directional and are most effective for fluids that have low concentrations of suspended solids.

Doppler flow meters operate by transmitting an ultrasonic wave from a transducer through the pipe wall and into the moving liquid. The sound wave is reflected by suspended particles or bubbles moving with the liquid and ultimately gathered by the receiving transducer. A frequency shift (Doppler effect) will occur that is directly proportional to the speed of the moving particles or bubbles. This shift in frequency is interpreted by the digital signal processor (DSP) and converted to a fluid velocity measurement.

Using its built-in hybrid technology, the DXN will automatically choose which type of flow measurement to read based on signal quality during operation. Regardless of the method used to determine velocity, multiplying the pipe’s cross-sectional area by the fluid velocity produces a volumetric flow rate. The measurement also presumes that the pipe is completely full during the measurement cycle.

When used in conjunction with flow measurement, temperature measurements can yield energy usage readings in the form of heat flow. To find the net heat loss or gain, energy usage is calculated by multiplying the flow rate of the heat transfer fluid by the change of heat content in the fluid after it has done some kind of work. An ultrasonic meter equipped with heat flow capabilities measures the rate and quantity of heat delivered or removed from devices such as heat exchangers. The instrument measures the volumetric flow rate of the heat exchanger liquid, the temperature at the inlet pipe and the temperature at the outlet pipe.

2017 Rental Fleet Purge:

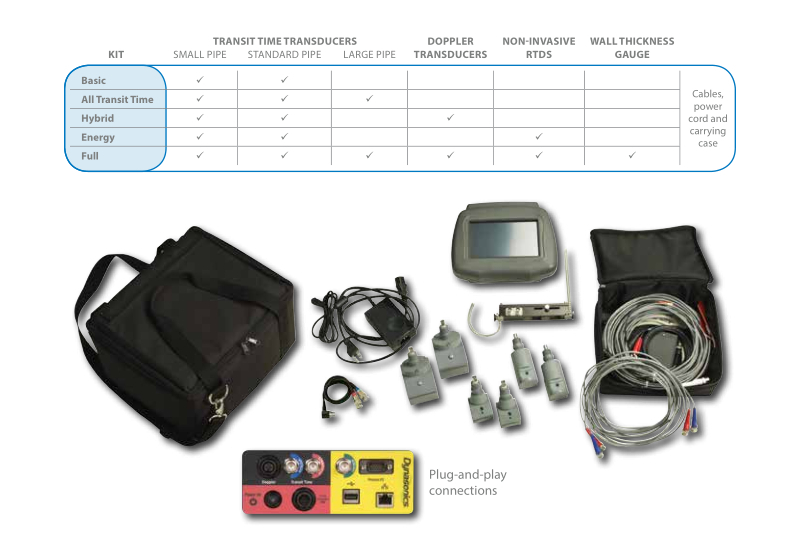

Kits include hardware, cables and cases.

After Fleet Discount: $7050

Retail: $8804

We have 2 units available at this price (each.) Both units come with current annual calibration certificates. These meters have long service lives and are actively supported by the manufacturer. Excess rental meters are retired annually to make room for new models.

These units are in good condition with minor cosmetic blemishes from use.

Included:

- DXN Transmitter

- Small Transit Time transducers

- Standard Transit Time transducers

- Large Transit Time transducers

- Doppler transducers

- Pipe wall tranducer

- USB Drive

- Auxiliary Output Box

- Serial Port Cable

- All Cables

- All Cases

At Derex, Inc. we have rented DXN's out for a wide variety of applications since their initial release in 2011. Our first purchased unit is still in operation.

These units set up easily, read flow accurately in any direction and work on any pipe. Straight pipe lengths are recommended (10 diameters up, 5 diameters down) but not critical for basic operations.

The NEW DXN is simply the best option for your next portable application, with true hybrid transit time and Doppler operation, an expandable 1GB data logger that takes readings over 50 times a second, and the ability to store site-specific parameters using plain English site descriptions. Take control of your toughest applications, add the DXN Portable to your flow measurement toolkit today.

Troubleshoot Flow Performance:

Designed for systems engineers to quickly troubleshoot problems and verify performance during system commissioning and diagnostics, the Dynasonics DXN portable clamp-on ultrasonic meter by Badger Meter is the perfect tool for any jobsite. Easy to install by clamping onto the outside of the pipe, the DXN measures flow using non-invasive ultrasonic sensors. Its portability makes it an excellent choice for measuring flows throughout the plumbing infrastructure to verify sensor, pump and valve performance.

With rapid response times, hybrid transit time and Doppler modes, the DXN capturesmore than 50 flow readings per second. Measurements are retained to memory stored in user-defined files and USB connectivity is included for easy downloads. With the only seven-inch, full-color advanced touchscreen interface in the industry, full-color graphing and wizard-based start-up configuration, the DXN is an excellent choice for easy programming and readability. Technicians can store site parameters using plain text and recall settings when they return for maintenance and diagnostic work in just a few touches.

Energy Monitoring: In addition to measuring liquid flow rate, the DXN is ideal for calculating hydronic energy usage. The built-in hydronic energy calculator makes it easy to facilitate energy studies on heating and cooling loops in building automation systems or in process applications. The DXN is equipped with heat flow capabilities designed to measure the rate and quantity of heat delivered or removed from devices such as heat exchangers. The DXN measures the volumetric flow rate of the heat exchanger liquid, the temperature at the inlet pipe and the temperature at the outlet pipe. Heat flow measurement can be delivered in Btu, Watts, Joules, Kilowatts, and others.

| Part Number | Description |

|---|---|

| D005-2109-013 | North American Plug (2 flat & 1 round prong; NEMA 5/15P |

| D005-2109-015 | UK Plug (3 rectangular prongs; BS1363A) |

| D005-2109-016 | European Plug (2 round prongs; CEE7/7 |

| D005-2109-017 | Japan Plug (2 flat & 1 round, JIS8303, w/ 3-2 prong adapter) |

| D005-2109-014 | China Plug (3 flat prongs; GB2099) |

| D005-2109-018 | Australian Power Plug (3 Flat Prongs; AS3112) |

| D005-2129-020 | Transit Time Cables, 20 ft (6 m) |

| D005-2129-050 | Transit Time Cables, 50 ft (15 m) |

| D005-2129-100 | Transit Time Cables, 100 ft (30 m) |

| D005-2130-020 | Doppler Cables, 20 ft (6 m) |

| D005-2130-050 | Doppler Cables, 50 ft (15 m |

| D005-2130-100 | Doppler Cables, 100 ft (30 m) |

| Part Number | Description |

| D010-2200-002-C | DTTSU Universal Small Pipe (Pipe OD 0.5 in. to 2.4 in.) |

| D071-0107-302-C | DTTR Standard Pipe (Pipe OD 2.0 in. to 98 in.) |

| D071-0110-200-C | DTTL Large Pipe (Pipe OD 16 in. to 120 in.) |

| D071-0112-001-C | DT94 Doppler Transducer (Pipe OD 1 in. to 60 in.) |

| DTTH-020-D000-N-C | DTTH High Temperature, Standard Pipe Kit (Pipe OD 2 in. to 98 in.) |

| Part Number | Description |

| D002-2007-004 | 0 - 392º F (0 - 200º C) RTD Silicone stretch tape |

| D002-2007-001 | 36 in. (914 mm) SS Hose clamp / transducer strap |

| D002-2007-005 | 72 in. (1829 mm) SS Hose clamp / transducer strap |

| D002-2011-014 | AcquaSonic 100 |

| D002-2011-001 | Acoustic couplant, grease (Dow 111), 150° F, 5.3 oz tube |

| D002-2011-011 | Acoustic couplant, paste high temperature, 5 oz tube, 392° F |

| D010-2102-310 | DTTR rail |

| D040-0115-003-T | Wall thickness gauge, 6 ft (1.83 m) |

| D010-3000-128 | Industrial RTD Kit 1 , 1000 Ohm, 392° F (200° C); 20 ft (6 m) cable |

| D010-3000-130 | Industrial RTD Kit 1 , 1000 Ohm, 392° F (200° C); 50 ft (15 m) cable |

| D010-3000-132 | Industrial RTD Kit 1 , 1000 Ohm, 392° F (200° C); 100 ft (30 m) cable |